Cycloid Clock

Motivation

At one point, I remember being shown a picture of a gear themed clock, and being rather annoyed that despite clocks using on gears and this clock being gear themed, it’s “pretty” gears didn’t do anything in the clock mechanism. They didn’t even spin! Ever since, I’ve had the idea in the back of my head to design a clock where all the functional gears are clearly visible.

It was during my final project for a CAD course that I decided to actually have a go at it, and came up with a design based on cycloidal drives. Specifically, I was inspired by Levi Janssen’s video showing a design for a single-plane, multistage cycloidal gearbox, and based my design for a clock of this style of gearbox. Cycloidal gearboxes are typically structured simiarly to a planetary reducer, but this concept rearranges the cycloidal drive so the output is the output is the ring gear, not the carrier. This allows multiple reducers to be chained together radially, in a single plane.

Initial Design

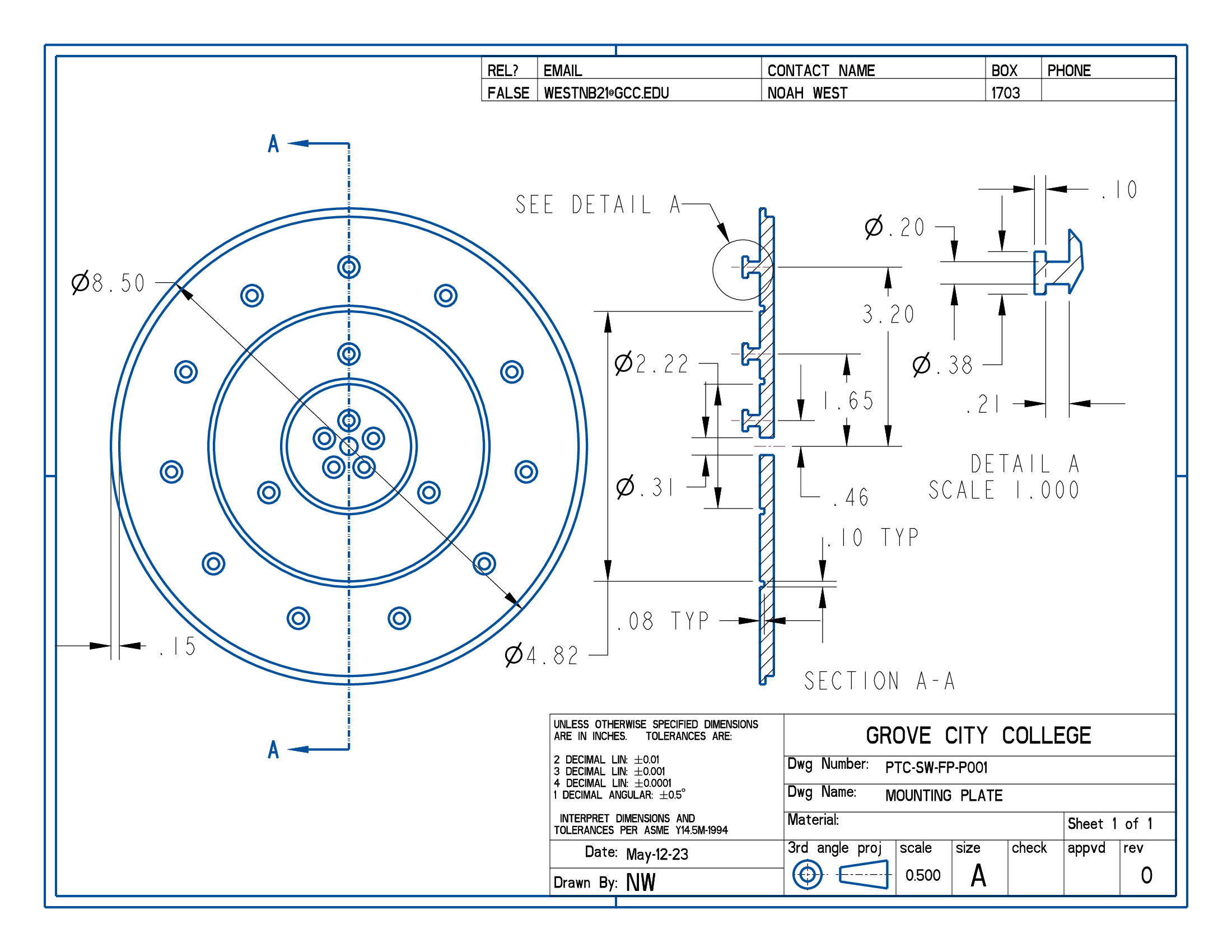

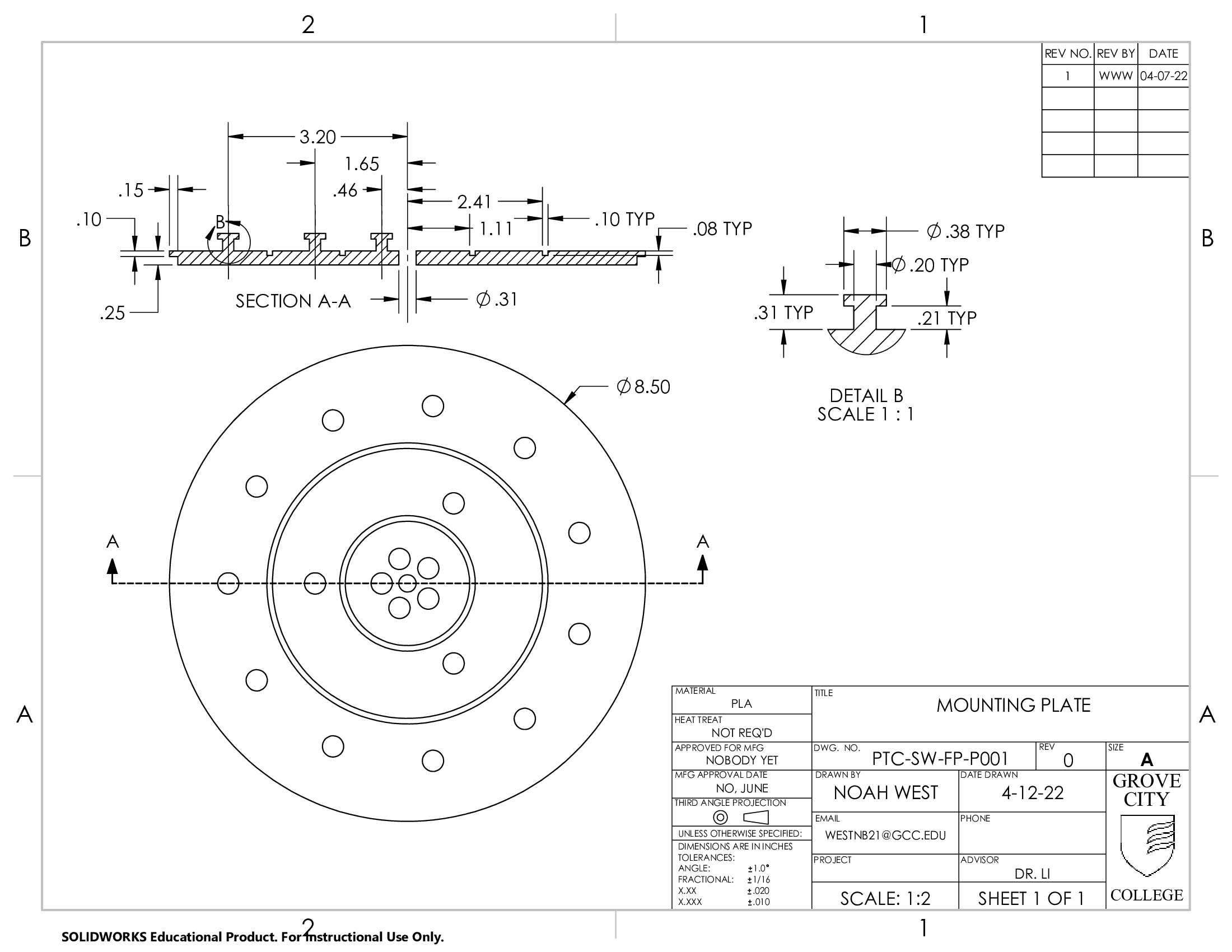

I was able to come to a design I was happy with by the deadline for the project, but the clock was rather large, had no power or drive system, and was not particularly manufacturable. But the mechanism itself was functional in CAD, and it served the purposes of the class project, which did not require me to actually build my design. Since that class focused on comparing 2 CAD softwares - CREO Parametric and Solidworks, I modeled my design and produced drawings in both, which are shown below. I find it interesting to compare the differences in visual style between the two softwares - CREO’s drawings(left) are much more striking.

Fixing it up

More recently, I decided to go back and redesign the clock into something both manufacturable and beautiful. The design I came up with would use stainless steel sheet for the gears, held onto the back plane with magnets and driven by a small stepper motor. I managed to shrink the design somewhat - making the design parametric allowed me to easily change the sizes and tooth counts of each stage, letting me iterate quickly through gear profiles and sizes. The CAD for this version was done using onshape, and is available online. I’ve also added a quick clip of the animated CAD model below - personally I find the rotation incrediby satisfying.

I have yet to fully test the design,and have some worries about the amount of friction it might have between stages. I’ve created a couple 3D printed models of single stages, but not gotten up the courage to actually order metal parts yet.